Carbon steel pipes, composed mainly of iron and carbon, have diverse properties and classifications relevant to specific industrial needs such as strength, ductility, corrosion resistance, and hardness. They are categorized into mild, medium, and high carbon steel based on carbon content and properties. These pipes offer advantages like strength, corrosion resistance, plasticity, and are used for fluid transportation, structural frameworks, heat exchangers, and piping systems. Various manufacturing processes such as seamless, welded, hot-rolled, and cold-drawn impact mechanical strength and surface finish. Their applications span across construction, manufacturing, aviation, automotive, and machinery industries. Further exploration can provide detailed insights into their versatility and customization options.

Carbon Steel Pipe Composition and Properties

@ Midjourney AI Image Prompt: /imagine prompt:Create an image of a cross-section of a carbon steel pipe, showcasing its composition and properties such as high strength, durability, and resistance to corrosion. Include detailed textures and markings. –v 6 –ar 16:9

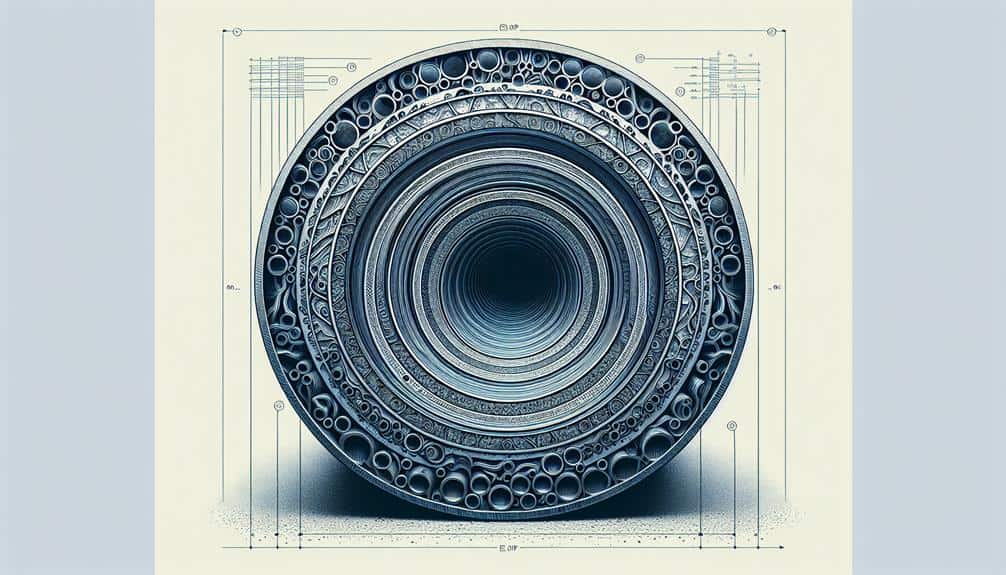

The composition of carbon steel pipes primarily consists of iron and carbon, with other trace elements such as manganese, silicon, and phosphorus influencing its properties.

These materials are carefully selected to guarantee the desired strength, ductility, and corrosion resistance in the final product.

Understanding the composition and properties of carbon steel pipes is essential for determining their suitability for various applications and industries.

Introduction to the main components of carbon steel pipe

Comprising various essential elements, the composition and properties of carbon steel pipes play a pivotal role in their structural integrity and functional performance. Carbon steel pipes typically consist of iron and carbon as the primary components, with carbon content ranging from 0.06% to 1.5%.

Other elements like manganese, phosphorus, sulfur, and silicon are added in specific quantities to enhance the pipes’ mechanical properties such as strength, ductility, and toughness. The composition of carbon steel pipes can vary based on the intended application, with different grades and classifications available to meet diverse industrial requirements.

Understanding the main components of carbon steel pipes is important for selecting the most suitable material for various applications.

Material Properties Analysis

In examining the material properties of carbon steel pipes, a thorough analysis of their composition and inherent characteristics is essential for understanding their structural behavior and performance in various applications. Carbon steel is primarily composed of iron and carbon, with trace amounts of other elements influencing its properties. The table below illustrates the material properties of carbon steel pipes, showcasing key attributes such as tensile strength, yield strength, elongation, and hardness.

| Property | Description |

|---|---|

| Tensile Strength | High strength and resistance to tension |

| Yield Strength | Point at which material begins to deform plastically |

| Elongation | Ability to stretch without breaking |

| Hardness | Resistance to deformation or indentation |

| Ductility | Ability to undergo significant plastic deformation before rupture |

What are the classifications of carbon steel pipes?

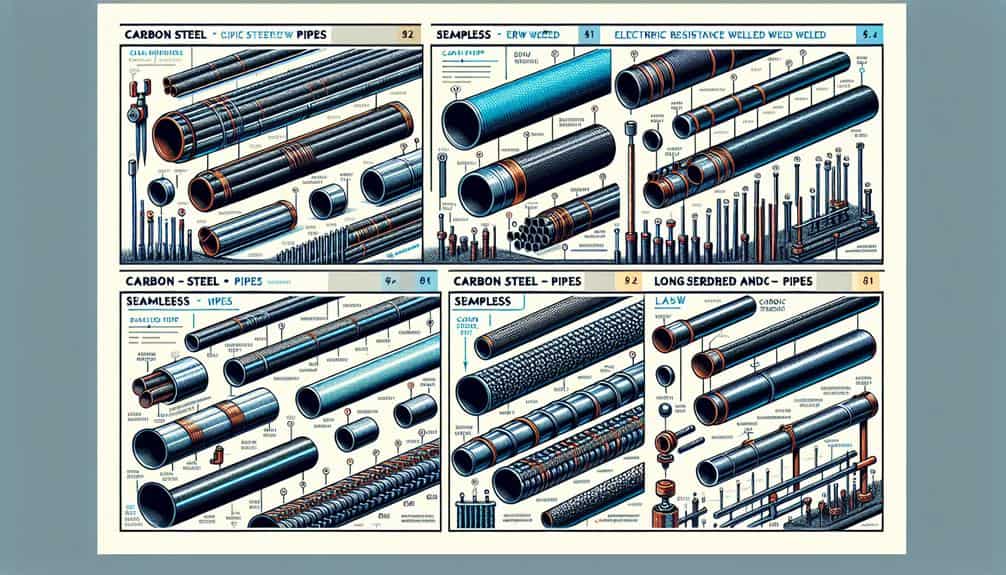

@ Midjourney AI Image Prompt: /imagine prompt:Create an image showcasing the different classifications of carbon steel pipes, including seamless, welded, ERW, and LSAW pipes. Show the varying sizes and finishes to illustrate their versatility. –v 6 –ar 16:9

Carbon steel pipes are categorized into different groups based on their carbon content and properties. These groupings include:

- Mild steel

- Medium carbon steel

- High carbon steel

Understanding these distinctions is essential for selecting the appropriate carbon steel pipe for specific applications.

Overview of different types of carbon steel pipes

Within the domain of steel pipe materials, the classifications of carbon steel pipes encompass a range of types distinguished by their composition and properties. The primary types include mild steel, medium carbon steel, and high carbon steel pipes.

Mild steel pipes have a low carbon content, making them versatile for various applications. Medium carbon steel pipes offer increased strength and hardness due to a higher carbon concentration. High carbon steel pipes have the highest carbon content, providing exceptional hardness and wear resistance.

Each type serves specific industrial needs based on their unique properties, such as strength, durability, and weldability. Understanding the distinctions between these classifications is essential for selecting the most suitable carbon steel pipe for a particular application.

Key features that distinguish different classifications

Key distinctions among the classifications of carbon steel pipes lie in their carbon content and corresponding mechanical properties, influencing their suitability for specific industrial applications.

Carbon steel pipes are broadly categorized into three main classifications: Mild steel, Medium carbon steel, and High carbon steel.

Mild steel pipes contain a relatively low carbon content, making them more ductile and suitable for general engineering purposes.

Medium carbon steel pipes have a higher carbon content, offering increased strength and hardness, ideal for applications requiring more robust materials.

High carbon steel pipes possess the highest carbon content, providing exceptional hardness and wear resistance, commonly used in specialized industrial settings where extreme durability is required.

Understanding these classifications is essential for selecting the most suitable carbon steel pipe for a particular application.

Advantages of Carbon Steel Pipe

@ Midjourney AI Image Prompt: /imagine prompt:Create an image showing a detailed cross-section of a carbon steel pipe, highlighting its durability, corrosion resistance, and versatility in various applications to illustrate the advantages of using carbon steel pipes. –v 6 –ar 16:9

Carbon steel pipes offer significant advantages in terms of strength and corrosion resistance, making them suitable for a wide range of applications.

Their plasticity and processability allow for easy fabrication and customization, ensuring efficient installation and maintenance in various industries.

These key qualities contribute to the popularity of carbon steel pipes due to their reliability, durability, and cost-effectiveness in demanding environments.

Strength & Corrosion Resistance

Strength and corrosion resistance are paramount factors contributing to the exceptional performance of carbon steel pipes in various industrial applications.

-

High tensile strength allows for the transportation of fluids under high pressure

-

Excellent resistance to corrosion extends the lifespan of the pipes in harsh environments

-

Superior impact strength minimizes the risk of damage during handling and installation

-

Good fatigue resistance guarantees long-term reliability in demanding operational conditions.

Plasticity and processability

The plasticity and processability of carbon steel pipes are significant attributes that contribute to their versatile application across various industries.

Carbon steel pipes exhibit excellent plasticity, allowing them to be easily formed and shaped into desired configurations without compromising their structural integrity. This characteristic makes carbon steel pipes highly adaptable for a wide range of construction and manufacturing processes.

Additionally, their superior processability enables efficient welding, bending, and machining operations, making them ideal for complex fabrication requirements.

The combination of exceptional plasticity and processability in carbon steel pipes guarantees that they can meet the diverse needs of industries such as construction, transportation, oil and gas, and manufacturing with precision and reliability.

Types of processes for carbon steel pipe

@ Midjourney AI Image Prompt: /imagine prompt:Create an image showcasing the various types of processes for carbon steel pipe, including seamless, ERW, and submerged arc welding, visually depicting their unique characteristics and applications. –v 6 –ar 16:9

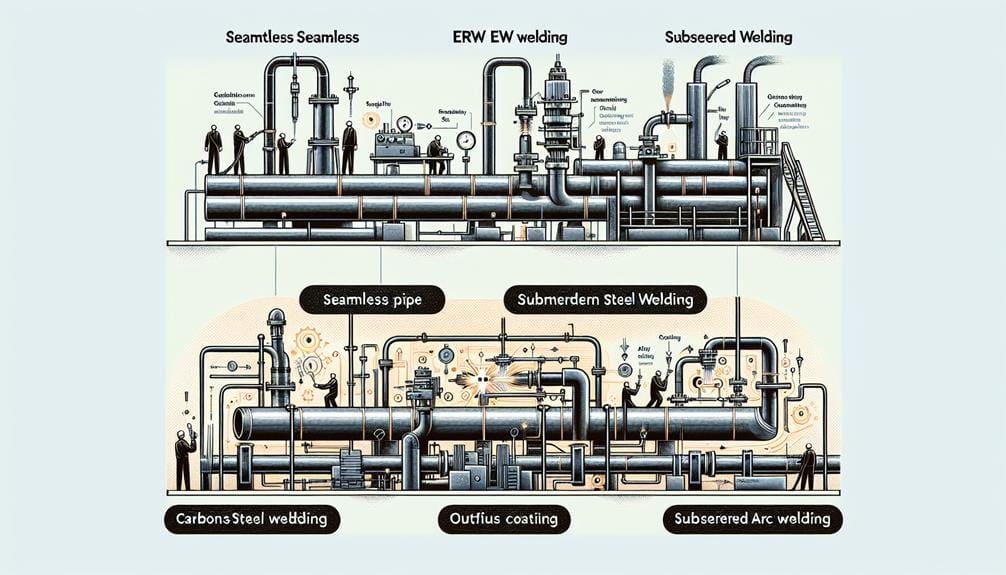

The production process of carbon steel pipes encompasses various methods such as seamless, welded, hot-rolled, and cold-drawn techniques. Each process has a distinct impact on the performance and characteristics of the pipe, influencing factors like strength, durability, and corrosion resistance.

Understanding the nuances of these manufacturing processes is essential in selecting the most suitable type of carbon steel pipe for specific applications.

Introduction to the production process of carbon steel pipe

Utilizing a precise manufacturing process, carbon steel pipes undergo various production methods to guarantee quality and reliability in their structural integrity.

-

Seamless Pipe Production: Utilizes a solid round steel ‘billet’ that is heated and pushed or pulled over a form until the steel is shaped into a hollow pipe.

-

Electric Resistance Welded (ERW) Pipe Manufacturing: Involves rolling metal plates to form pipes and then welding the seam.

-

Submerged Arc Welding (SAW) Process: Uses a granulated flux to create protective gas bubbles that shield the weld.

-

Double Submerged Arc Welding (DSAW) Technique: Welds two submerged arcs simultaneously to increase efficiency and precision in large-diameter pipes.

The influence of different processes on the performance of the pipe

Different production processes employed in the manufacturing of carbon steel pipes have a significant impact on their performance characteristics and structural integrity.

Processes such as seamless pipe production involve heating a solid steel billet and then piercing it to form a hollow tube, resulting in pipes with enhanced strength and corrosion resistance due to the absence of seams.

On the other hand, welded pipe manufacturing utilizes welding techniques to join steel sheets or strips, offering cost-effective solutions for various applications.

Additionally, processes like hot rolling and cold drawing further refine the pipe’s properties, affecting its mechanical strength, dimensional accuracy, and surface finish.

Understanding the influence of these processes is essential in selecting the most suitable carbon steel pipe for specific industrial requirements.

Uses of Carbon Steel Pipe

@ Midjourney AI Image Prompt: /imagine prompt:Create an image showing various industries such as construction, oil and gas, and automotive using carbon steel pipes for applications like structural support, transportation of fluids, and machinery components. –v 6 –ar 16:9

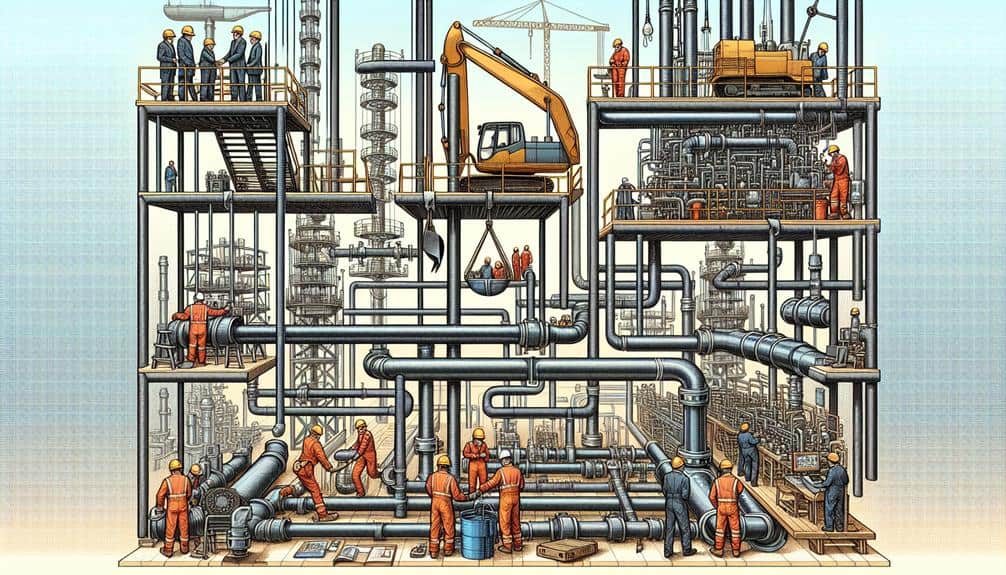

Carbon steel pipes find extensive applications in the construction, manufacturing, and various other industries. Their versatility allows for use in projects ranging from water and gas pipelines to high-pressure boiler pipes and oil drilling equipment.

Additionally, carbon steel pipes are often customized to meet specific requirements for specialized projects, showcasing their adaptability and utility in various sectors.

Applications in construction, manufacturing and other industries

In construction, manufacturing, and various other industries, the application of carbon steel pipes is essential for ensuring structural integrity and operational efficiency.

-

Transportation of fluids and gases under high pressure

-

Fabrication of structural frameworks and support systems

-

Heat exchangers and boilers in thermal power plants

-

Piping systems in chemical processing plants

Uses of CarbCustomization services for branded customizationon Steel Pipe in Special Projects

Amidst specialized projects, the utilization of carbon steel pipes plays a pivotal role in ensuring structural integrity and operational efficiency across a spectrum of industries. In special projects, carbon steel pipes are often employed for their exceptional strength, durability, and resistance to corrosion.

These pipes find extensive use in critical applications such as high-pressure boiler systems, thermal equipment for generating steam, and pipelines for transporting oil, gas, and chemicals. Additionally, in industries like aviation, automotive, and machinery, carbon steel pipes are crucial components for ensuring the reliable operation of various systems.

The versatility and reliability of carbon steel pipes make them indispensable in special projects where performance and longevity are paramount.

Customization services for branded customization

@ Midjourney AI Image Prompt: /imagine prompt:Create an image showcasing various types of carbon steel pipes, each customized with a different branded logo. Include examples of different sizes, coatings, and fittings to highlight customization options. –v 6 –ar 16:9

Customization services for branded customization in the carbon steel pipe industry offer customers the advantage of tailor-made solutions to meet specific requirements.

Brands that provide customization services often accompany their products with thorough after-sales support, ensuring a seamless experience for the end-user.

This level of personalized attention enhances customer satisfaction and builds trust in the brand’s commitment to quality and service.

Advantages and feasibility of customization options

Enhancing carbon steel tube properties through tailored modifications offers a strategic edge in meeting diverse industrial requirements efficiently.

-

Customization allows for precise dimensional requirements to be met

-

Tailored material composition enhances specific performance characteristics

-

Brand-specific coatings and finishes can be applied for enhanced durability

-

Customized packaging options guarantee safe transportation and storage

After-sales service and support from the brand

The provision of thorough after-sales service and support from the brand plays a pivotal role in ensuring the successful implementation of customization services for branded modifications.

When considering carbon steel pipe customization, it is essential to partner with a brand that offers extensive assistance post-purchase. This support may encompass technical guidance on customization options, troubleshooting potential issues that may arise during modification processes, and ensuring that the final product meets the required specifications and standards.

Reliable after-sales service also includes prompt responses to inquiries, efficient handling of warranty claims, and continuous support throughout the customization journey. By choosing a brand that prioritizes after-sales service, customers can enhance the overall success and satisfaction of their customized carbon steel pipe solutions.

Frequently Asked Questions

What Are the Key Differences Between Seamless and Welded Carbon Steel Pipes?

Seamless carbon steel pipes lack welded seams, offering superior strength and reliability, ideal for high-pressure applications. Conversely, welded pipes feature welded joints, slightly lower in strength but often more cost-effective and suitable for less demanding environments.

How Does the Carbon Content in Carbon Steel Pipes Affect Their Properties and Applications?

The carbon content in carbon steel pipes greatly influences their strength, hardness, and weldability. Higher carbon levels enhance hardness but reduce ductility. Proper selection based on carbon content is essential to guarantee desired properties for specific applications.

Can Carbon Steel Pipes Be Used in High-Temperature and Corrosive Environments?

Carbon steel pipes can be suitable for high-temperature and corrosive environments depending on their specific grade and protective coatings. Factors like carbon content, alloying elements, and surface treatments play important roles in enhancing their resistance to extreme conditions.

What Are the Common Challenges Faced During the Fabrication of Carbon Steel Pipes?

Common challenges in fabricating carbon steel pipes include maintaining precise dimensions, controlling welding heat input to prevent distortion, ensuring proper material selection for desired properties, managing corrosion resistance during processing, and adhering to stringent quality standards.

Are There Any Specific Regulations or Standards That Govern the Manufacturing and Use of Carbon Steel Pipes in Different Industries?

Regulations and standards governing carbon steel pipe manufacturing vary by industry, including national, American, and Japanese specifications. Adherence guarantees quality, safety, and performance in applications such as water, oil, machinery, and chemical sectors. Meeting these standards is essential for industry integrity.

Conclusion

To sum up, carbon steel pipes offer a wide range of properties and benefits that make them essential in various industrial applications.

While some may argue that carbon steel pipes can be susceptible to corrosion, proper surface treatment and maintenance can mitigate this issue effectively.

Overall, the versatility, durability, and cost-effectiveness of carbon steel pipes make them a preferred choice for engineering projects across different sectors.