Choosing the top carbon steel pipe vendor involves evaluating material quality, production capacity, technical expertise, and dependable delivery schedules. Consider reputable manufacturers with proficiency in material selection and industry standards compliance. Evaluate production capabilities to meet quantity and lead time needs. Prioritize suppliers with a track record of on-time deliveries and positive customer feedback. Understanding these key factors is crucial for successful partnerships in the carbon steel pipe industry. This knowledge guarantees excellent outcomes for projects requiring high-quality pipes. Find out more about what to look for in a reliable supplier to enhance your decision-making process.

Key Takeaways

- Evaluate reputation, industry experience, and certifications for quality assurance.

- Consider production capacity, timely delivery, and technical expertise.

- Assess customer support, pricing transparency, and customization options.

- Prioritize compliance, reliability, and customer satisfaction.

- Seek long-term partnerships, consistent quality, and efficient communication.

How to choose a suitable carbon steel pipe manufacturer?

When searching for a suitable carbon steel pipe manufacturer, it is important to carefully evaluate different factors to guarantee excellent quality and reliability in the products supplied. Material selection plays a pivotal role in determining the quality and performance of carbon steel pipes. A reputable manufacturer should have expertise in choosing the appropriate materials to guarantee durability and efficiency in various applications.

Production capacity is another key factor to evaluate when selecting a carbon steel pipe manufacturer. The manufacturer’s ability to meet your requirements in terms of quantity and lead times is essential to avoid delays in your projects. Evaluating the technical expertise of the manufacturer is important to make sure that they have the knowledge and capabilities to produce high-quality carbon steel pipes that meet industry standards.

Furthermore, assessing the delivery timelines provided by the manufacturer is crucial to align with your project schedules. Customer feedback can offer valuable insights into the manufacturer’s reputation, product quality, and service levels. Choosing a manufacturer with positive customer feedback can increase the likelihood of a successful partnership and satisfactory product outcomes.

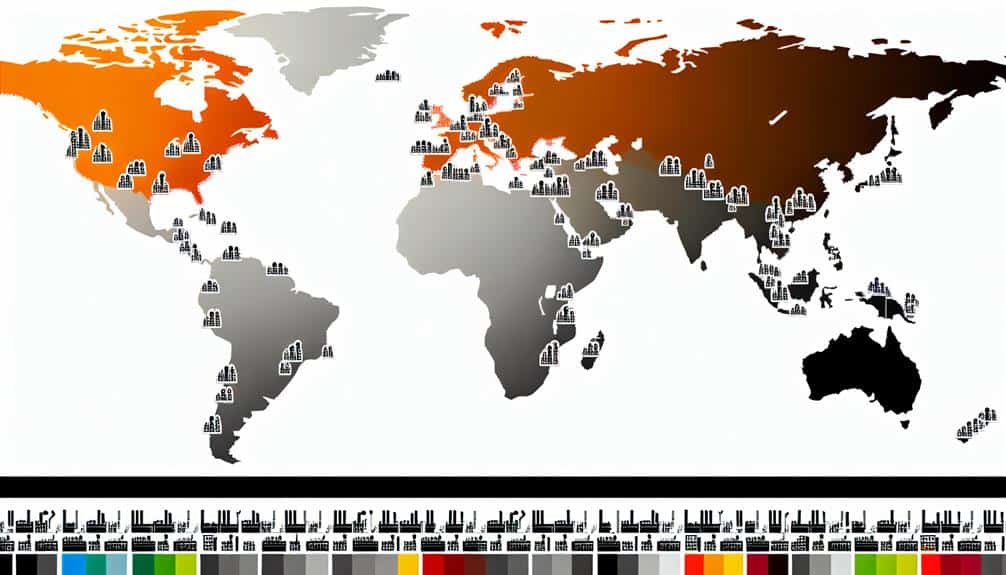

Global Carbon Steel Pipe Manufacturers by Country

Analyzing the distribution of global carbon steel pipe manufacturers by country provides valuable insights into the geographical concentration of industry expertise and production capabilities. Country comparison reveals that Japan, India, the USA, and China are key players in the carbon steel pipe manufacturing industry. Each country brings its unique material expertise, industry experience, production capacity, and global reach to the market.

Japanese manufacturers, such as MORY INDUSTRIES INC., are known for their specialization in welded carbon steel products and stainless steel. In India, companies like RELIABLE PIPES & TUBES LTD. have a strong focus on providing piping solutions and carbon steel pipes with a history dating back to 1975. Meanwhile, USA-based manufacturers like Webco excel in carbon tubing and piping products, offering a wide range of customized solutions. China’s SHAANXI SHEW-E IRON & STEEL CO., LTD. specializes in seamless steel pipes for various applications, showcasing a diverse product portfolio to meet customer needs globally.

Supplier Evaluation Guide

When evaluating carbon steel pipe suppliers, it is vital to focus on three key points:

Quality & Reliability, Service & Support, and Costs & Benefits.

Ensuring high standards of quality and reliability in the products provided, gauging the level of service and support offered, and considering the overall costs versus benefits are essential factors in selecting the most suitable supplier for carbon steel pipes.

These points are fundamental in making informed decisions that align with the requirements and expectations of the project or application at hand.

Quality & Reliability

A critical aspect in the process of selecting carbon steel pipe suppliers for industrial applications is evaluating the quality and reliability of their products and services. Material sourcing plays an important role in determining the overall quality of the carbon steel pipes.

It is essential to assess the supplier’s production efficiency to guarantee timely delivery without compromising on quality. Performance testing should be conducted to verify the pipes meet industry standards and specifications.

Customer satisfaction is a key indicator of a supplier’s reliability and commitment to quality. By considering these factors, businesses can make sure they partner with a reputable carbon steel pipe supplier that delivers high-quality products consistently.

Service & Support

When assessing carbon steel pipe vendors for industrial applications, a vital aspect to consider is the level of service and support they provide to ensure smooth project execution. Ensuring customer satisfaction through thorough technical assistance, product training, after-sales service, and troubleshooting support is paramount.

A reliable supplier should not only offer high-quality carbon steel pipes but also be prepared to assist clients in various aspects beyond the purchase. From initial consultations to post-installation support, a supplier’s commitment to service excellence can greatly impact project timelines and overall success.

As such, selecting a partner that values service and support as much as product quality is essential for a seamless industrial experience.

Costs & Benefits

Evaluating the cost-effectiveness and advantages of potential carbon steel pipe suppliers is a critical component of the Supplier Evaluation Guide for industrial applications. Effective cost analysis, material selection, and budget planning are essential for successful project assessment and risk management. To aid in this evaluation process, a comparison table is provided below to assist in identifying the key features of different suppliers.

| Supplier | Specialization |

|---|---|

| MORY INDUSTRIES INC. | Welded carbon steel products, stainless steel |

| RELIABLE PIPES & TUBES LTD. | Piping solutions, carbon steel pipes |

| Webco | Carbon tubing, piping products |

| Ozairtradelink | Carbon steel tubes, metal products |

Carbon Steel Pipe Manufacturers List

Among the notable carbon steel pipe manufacturers are MORY INDUSTRIES INC., RELIABLE PIPES & TUBES LTD., Webco, Ozairtradelink, SHAANXI SHEW-E IRON & STEEL CO., Tesco Steel & Engineering, and JF Engineering Products LLP, offering a range of quality products for various industrial applications worldwide.

These manufacturers excel in providing diverse material specifications, high production capacities, extensive customization options, significant industry experience, and reliable delivery timelines.

MORY INDUSTRIES INC. specializes in welded carbon steel and stainless steel products, holding certifications for environmental and quality management.

RELIABLE PIPES & TUBES LTD., established in 1975 in India, focuses on piping solutions and carbon steel pipes with a strong emphasis on quality assurance.

Webco, founded in 1969 in the USA, offers expertise in carbon tubing, including welded and cold-drawn tubing, and provides tailored solutions to meet customer needs.

SHAANXI SHEW-E IRON & STEEL CO., LTD., established in 2008 in China, specializes in seamless steel pipes and specialty metals for applications such as boilers, petrochemicals, and automobiles.

Tesco Steel & Engineering, founded in 2017 in India, is known for its diverse product range of steel fittings for various industrial applications.

JF Engineering Products LLP, located in Mumbai, India, focuses on industrial fasteners manufacturing and distribution, particularly stainless steel fasteners, with certifications for adherence to ISO and ASTM standards.

Brand Introduction

The introduction of brands within the carbon steel pipe industry plays a crucial role in establishing market presence and showcasing product offerings to potential consumers. When evaluating carbon steel pipe suppliers, brand reputation stands out as a crucial factor. A brand’s reputation reflects its consistency in delivering quality products and services, as well as how it is perceived by customers and competitors within the industry.

Production capacity is another essential aspect to take into account, as it directly impacts a supplier’s ability to meet varying demands promptly and efficiently.

Furthermore, the process of material sourcing is fundamental in determining the quality and reliability of carbon steel pipes. Industry experience is a key indicator of a brand’s knowledge and expertise in the field, showcasing its ability to navigate challenges and deliver solutions effectively. Customer reviews provide valuable insights into the overall satisfaction levels and experiences of previous clients, serving as a demonstration of the brand’s performance and customer service standards.

Frequently Asked Questions

What Are the Key Factors to Consider When Selecting a Suitable Carbon Steel Pipe Manufacturer?

When choosing an appropriate carbon steel pipe producer, important factors to evaluate include:

- Product quality

- Pricing approach

- Customer support

- Lead times

- Industry expertise

Evaluate the producer’s compliance with quality standards, competitive pricing, responsiveness to inquiries, ability to meet delivery schedules, and depth of experience in the sector. Assessing these factors will guarantee a dependable partnership for your carbon steel pipe requirements.

How Does the Geographical Location of a Carbon Steel Pipe Manufacturer Impact the Selection Process?

Geographical location influences carbon steel pipe supplier selection through multiple facets. Environmental impact is tied to transportation emissions, affecting sustainability efforts.

Production capacity may vary based on proximity to raw materials or manufacturing centers. Quality control can be influenced by regional standards and regulations.

Cost efficiency is impacted by shipping costs. Lead times are subject to distance, affecting project timelines. Strategic evaluation of these factors guarantees an ideal supplier choice.

What Criteria Should Be Included in a Comprehensive Supplier Evaluation Guide for Carbon Steel Pipe Manufacturers?

When assessing carbon steel pipe manufacturers, a thorough guide should cover several key aspects:

-

Supplier qualifications, including certifications and industry reputation.

-

Production capacity, which must align with demand and be supported by effective quality control processes to ensure product integrity.

-

Pricing strategies that are competitive in the market.

-

Customer service excellence, which is essential for a successful partnership.

A detailed evaluation guide is crucial for selecting the most appropriate carbon steel pipe manufacturer to meet specific project requirements.

Are There Any Specific Details or Considerations to Keep in Mind When Looking at a List of Global Carbon Steel Pipe Manufacturers by Country?

When evaluating global carbon steel pipe manufacturers by country, important factors include geographical considerations, quality assurance, material specifications, industry certifications, and price competitiveness.

Geographical proximity can impact logistics and lead times. Quality assurance guarantees compliance with standards. Material specifications must meet project requirements. Industry certifications validate product quality. Price competitiveness affects overall project costs.

Evaluating these aspects can help in selecting the most suitable supplier for specific project needs.

Can You Provide Insights Into the Brand Introduction of a Carbon Steel Pipe Manufacturer and How It Can Influence the Decision-Making Process?

Brand introduction of a carbon steel pipe manufacturer greatly influences decision-making. Reputation, market presence, and certifications showcase product quality. Competitive pricing, delivery times, and customer support impact satisfaction.

Industry experience and references validate reliability. Incorporating these aspects aids in a thorough evaluation for selecting a manufacturer.

As a figure of speech, the brand introduction acts as a guiding star in the vast expanse of industrial suppliers, illuminating the path to best partnership choices.

Conclusion

In summary, it is crucial for industrial operations to carefully select a reputable carbon steel pipe supplier to guarantee project success.

By following a thorough evaluation process and considering key factors such as product quality and adherence to industry standards, businesses can make informed decisions.

Choosing the right partner, such as MORY INDUSTRIES INC. or RELIABLE PIPES & TUBES LTD., can lead to seamless project execution and maximum efficiency.

Remember, the devil is in the details when it comes to selecting the best supplier.